The effect of frequency in

welding thick-walled HFI pipes

Hendrik Loebbe

Introduction

The use of High Frequency

Inductive (HFI) welding is a highly productive process for the

manufacture of longitudinally welded pipes from hot‑rolled strip.

Longitudinally welded HFI pipes are nowadays used in the most diverse

range of applications. Typical of such uses are, for example, pipelines

for the conveyance of liquid and gaseous hydrocarbons, potable and

utility water, brine, district heating systems, hollow sections and Oil

Country Tubular Goods (OCTG). Mannesmann Fuchs Rohr (Siegen and Hamm,

Germany) produces HFI pipes in O.D. 4”-20” (114.3-508.0 mm) with wall

thicknesses up to t = 0.81” (20.6 mm). Special requirements originating

from the offshore sector are thus also fulfilled via the use of

high‑quality grades of steel with large pipe‑wall thicknesses [1]. In

this sector, HFI pipes are increasingly coming into use in the offshore

sector, in competition with SAW and seamless pipes. Not least important

of all in this context is the trend toward the production of ever

thicker‑walled HFI pipes. The technological preconditions necessary for

this purpose, in terms of HFI welding technology, are discussed, with

attention to normative aspects, in the following essay, with prime

emphasis attended to the topic of "welding frequency".

The welding process

The welding process is the

central operation in the chain of production processes involved in the

manufacture of pipes from hot‑rolled wide strip. One can differentiate

essentially between fusion welding and pressure welding, with a number

of diverse process variants [2]. Fusion welding methods take the form of

the submerged‑arc and gas metal-arc welding processes for production of

longitudinally welded and spiral‑welded pipes. The pressure welding

processes include among others the low-frequency and the high‑frequency

welding, the latter being the subject of this essay. There are in the

relevant literature no generally applicable differentiations based, in

particular, on physical principles and/or phenomena for definition of

the high‑frequency technology frequency range, particularly in the case

of welding. Minimum frequency values for HF welding can be found in

international product standards and specifications for pipes, such as EN

10208-2, ISO 3183-2, ISO 3183-3 and API Specification 5L

[3],[4],[5],[6]. Here, a frequency of f ≥ 100 kHz is required for HF‑welded

pipes, irrespective of all other boundary conditions (API Spec. 5L, PSL 2

only). No upper frequency limit is stated, however. Elsewhere, the term

"high‑frequency" is defined, for example, as the "f = 50 to 10,000 kHz"

or "f = 10 to 5,000 kHz" frequency range [7],[8].

It is possible, in

principle, to differentiate in the context of HF welding processes

between conductive and inductive transfer of energy. In the case of

conductive technology, input of energy is accomplished with copper

contacts via the surface of the pipe, with the resultant possibility of

strikes and burns on this surface. In inductive systems energy transfer

is accomplished without contact. In both cases, it must essentially be

assured that the necessary "skin effect" is generated. Utilizable

minimum frequencies were in the past the result primarily of the

thermionic valve‑based generator technology and the power thus

available. The advance of transistor technology permits the use of lower

frequencies combined with higher power, particularly in the case of the

HFI process. This is useful, in particular, for welding of thick‑walled

HFI pipes which is one factor permitting the increased use of such

longitudinally welded pipes in offshore application. Anyway, the minimum

frequency in this context is 100 kHz, in order to fulfill the

requirements of the various standards and specifications.

Physical effects

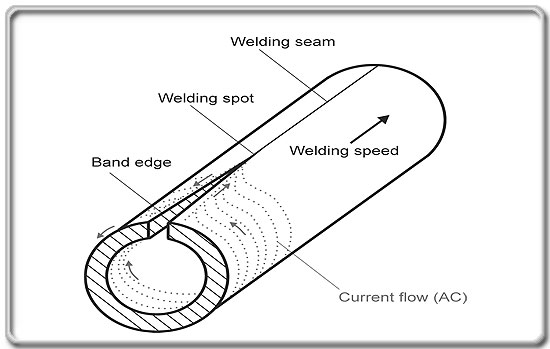

In both conductive and

inductive HF welding, the principle is based on the fact that a current

flows on the pipe surface and the band edges (Fig.

1). This high‑frequency current

flows on the surface of the pipe via the edges of the strip to the

welding point at which the melted strip edges are forced together and

welded.

Fig. SEQ Fig. \* ARABIC

1: Current flow on the surface of the pipe

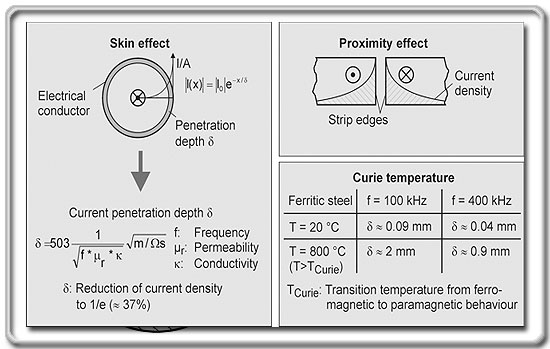

The precondition for the

achievement of the flow of current on the pipe surface and on the edges

of the strip is the so‑called "skin effect" (Fig.

2). A further increase in current

density on the strip edges results in the "proximity effect". The

current's penetration depth is determined essentially by the temperature

of the material relative to the Curie temperature.

Fig. SEQ Fig. \* ARABIC

2: Basic principles [9],[10],[11]

The skin effect causes on

the surface of a conductor an increase in current density dependent on

frequency. Current density drops in the form of an e‑function as

distance from the conductor edge increases. Reduction of current density

to 1/e (approx. 37 %) is defined as current penetration depth. The

influencing factors are material‑dependent characteristics and

frequency. Frequency thus provides a method of controlling penetration

depth and temperature increase in the boundary zone of the band edges.

It must be noted that influence is relative to the square root and that

a quadrupling of frequency thus results in a halving of penetration

depth. In the case of HFI welding, the skin effect results in the

current flowing only on the pipe surface and in heating up of the strip

edges to welding temperature at the welding point.

The proximity effect also

causes a further increase in current density in the strip edge zone.

This effect is based on the fact that the charges, with currents flowing

in opposite directions, attract each other.

The third aspect with a

significant influence on the profile of temperature of the strip edge is

the excess of Curie temperature. This occurs, in accordance with the

iron‑carbon diagram, at T = 769 °C [2]. Ferritic steels exhibit

ferromagnetic behaviour below this temperature, and paramagnetic

behaviour above it. This has a significant effect on the current's

penetration depth. Penetration depth will rise, for example, around

22‑fold if the temperature at the strip edge rises above the Curie

temperature during HF welding.

The dependence of

temperature profile on frequency

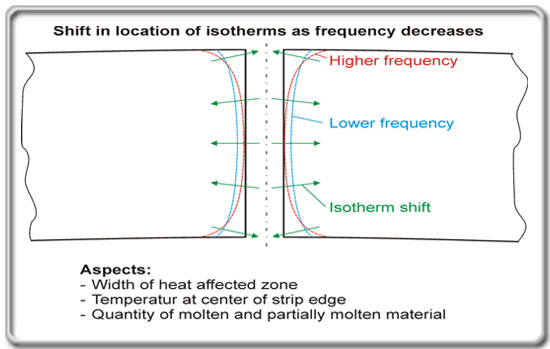

The heating profile at the

edges of the strip can be manipulated, inter alia, via the selection of

frequency. It must be technologically assured that the skin effect is

achieved. The penetration depth of the heat‑affected zone (HAZ),

particularly at the center of the strip, is generally increased as

frequency decreases. The irregular configuration of the heat‑affected

zone, in the form of an hour‑glass, is lessened. This results in the

steel's welding temperature also being reached with processing certainty

at the center of the strip (Fig. 3,

Fig. 4). The

overheated corners of the strip edges possible at higher frequencies are

eliminated at lower ones, such as may be used in HFI process.

Fig. SEQ Fig. \* ARABIC

3: The effects of frequency on temperature profile in connection with

HFI welding

Fig. SEQ Fig. \* ARABIC

4: Heating profile at strip edges in production of thick-walled pipe

Only a few systematic

investigations of the influence of frequency on the process, on the one

hand, and on the technological properties of the pipe, on the other

hand, have been published. A number of these are discussed below.

The development of

transistor technology has made it possible to use frequencies below

f = 200 kHz for the purpose of HFI welding [12]. In the past, due to

valve‑based technology, the minimum frequency from a technological and

economic standpoint was, on a system‑engineering view, around

f = 250 kHz. Extremely fast MOSFET transistors have been in use in HFI

resonant circuits since the mid‑1980s; in addition, high‑current IGBT

transistors have increasingly become established in the welding‑systems

sector in around the last ten years, and thus permit frequencies down to

100 kHz for HFI welding [12],[13]. Both types of transistor are nowadays

used, depending on their strengths and the corresponding requirements.

The potential for technologically and economically rational use of

frequencies down to 100 kHz for HFI welding must, as already mentioned

above, also be viewed in close conjunction with the trend toward

production of ever thicker HFI pipe‑wall thicknesses.

Finite Element Method

(FEM) analysis studies have been performed into the influence of various

process parameters, and frequency, in particular, on the HFI welding

process [14],[15],[16]. The following influencing factors were examined

here: welding angles, distance of the welding point from the inductor,

resilient flexing of the strip edge, welding speed and welding

frequency. The reasons for performance of these published investigations

can be found in welding problems encountered in the production of pipes

with a wall thickness of t = 12.7 mm, which were attributed to a cold

strip center. It was ascertained that all the factors investigated

significantly influence the configuration of the heat profile in the

edge of the strip. As far as frequency is concerned, the frequency

100 kHz cause a much more uniform increase in temperature up into the

center of the strip edge than the frequency 300 kHz. The percentage of

melted material in the vicinity of the corners of the strip edge falls

significantly as frequency falls, thus reducing burn‑off of these

corners. It becomes apparent in the relevant investigations, however,

that the other parameters examined also have a significant influence on

the heat profile in the edge of the strip material and must therefore

also be used for description of the process. A factor of two in the case

of the angle of approach of the weld vee, for example, thus has a

greater influence than a factor of three for frequency.

In contrast to this, there

are also studies concerning the influence of frequency, the essential

criteria of which are the spread of the heat‑affected zone and thus

necessary power [17],[18]. These investigations are also unanimous in

stating that penetration depth in the f = 100 to 600 kHz range becomes

greater as frequency falls. The unbalanced conclusion of these authors,

failing to take account of other technological boundary conditions, is

in this case that higher frequencies are assumed to be more economical,

since a greater penetration depth would be a waste of energy, and that

higher power is therefore necessary. With respect to the complete

melting of the edges of the strip, this must be critically evaluated,

however. At lower frequencies in the case of HFI welding, heating up to

the center of the strip is assured with processing certainty even in the

case of greater wall thicknesses.

Practice also demonstrates

that the process as a whole, including the environment in which it takes

place, must also be studied, in addition to these physical principles.

If the process chain, including upstream and downstream facilities, is

thus examined, it will be necessary, for example, to analyze the

interaction of possible power input and welding speed. The principal

objective, that of producing, cost‑effectively, pipes which meet the

specification, must continuously be borne in mind during all such

deliberations, however.

The use of

adjustable‑frequency HF generators is recommended for large

wall‑thickness/diameter ratios [19]. A significant advantage is,

accordingly, the use of a frequency tailored to the particular

application, in order to minimize the hour glass and therefore the

"waist‑like" constriction of the HAZ, and thus create a very homogeneous

weld, with a uniform hardness distribution. The author does not state

exemplary frequencies for specific applications, however.

All in all, these

investigations indicate that the beneficial effects of a lower frequency

on the HFI welding process are clear. There are, on the one hand, only

few well founded publications on this subject and, on the other hand,

diverse conceptual interpretations, however. Practice at Mannesmann

Fuchs Rohr indicates that a uniform heat‑affected zone and extremely

good welding results are achieved. Uniform melting of the entire edge of

the strip is assured, particularly in production of pipes with large

wall thicknesses of up to t = 20.6 mm.

Control of heat input to

the edges of the strip

As already outlined above,

heat input and the heat profile in the edge of the strip in HFI welding

depend not only on the frequency used, but also on a large number of

other influencing factors. Major influencing factors

are shown in Fig. 5. These can be subdivided into six

groups, i.e., ambient media, energy conversion at the inductor,

strip‑edge condition, impeder state and arrangement, welding speed and

welding vee. A total of sixteen different parameters, of which current

frequency is one, are shown here. Frequency is, without doubt, an

important factor in control of the welding process and thus the welding

result, but can only be examined in context, together with the other

parameters. A number of results from [14],[15],[16] on this subject have

already been discussed. Detailed examination of the influence of each

individual factor is not the subject of this essay.

Fig. SEQ Fig. \* ARABIC

5: Factors influencing heat input

The frequency and power of

HFI systems

Two types of transistor

are in general use in HFI welding systems at present [12],[13],[20].

"Metal Oxide Semiconductor Field Effect Transistors" (MOSFET) are used

in the f > 150 kHz range. "Insulated Gate Bipolar Transistors" (IGBT)

make it possible to provide power of adequate magnitude for the welding

of pipes even at f < 150 kHz.

The spectrum of available

frequencies and powers for HFI systems is shown on the basis of system

manufacturers information in Fig. 6.

Both technological, economic and normative aspects must be taken into

account in selection of frequency (new investments, order‑specific). In

the case of a new investment, in particular, the entire plant structure,

including upstream and downstream facilities, must also be taken into

account.

Fig. SEQ Fig. \*

ARABIC 6: HFI systems: Frequency and power ([21],[22],[23],[24],[25] in

2006)

Summary

The further development of

transistors and their use in the field of HFI welding have resulted in

the past approximately ten years in significantly broadened potentials

in plant and system‑engineering terms, particularly with respect to the

utilizable frequencies. On the product side, on the other hand, the

trend toward thicker‑walled HFI pipes, which are increasingly coming

into use in the offshore sector, has continued. At present, and less for

technological than for normative reasons, the frequencies used are

subject to specific minimal values. Such process‑engineering

restrictions in product‑specific standards should, however, be consigned

to history, and thus no longer stand in the way of system‑engineering

progress. Prime emphasis in this context should be directed solely at

the product properties of the pipes for the particular application. It

must, in general, be noted that HFI welding cannot be defined in terms

of "frequency" as the sole influencing factor. Rather, the interaction

of a large range of factors is of great importance from a

production‑engineering viewpoint.

References

[1]

Zimmermann,

B.; Brauer, H.; Marewski, U.: Development of HFIW line pipe for offshore

applications. “4th International

Conference on Pipeline Technology”, 9.‑13.05.2004, Ostende, Belgium

[2] Sommer, B.: Stahlrohr

Handbuch. 12th edition, Vulkan‑Verlag Essen, 1995

[3] N.

N.: Technical delivery conditions for steel pipes for use with

combustible fluids. EN 10208‑2, August 1996

[4] N.

N.: Petroleum and natural gas industries – Steel pipe for pipe lines –

Technical delivery conditions. ISO 3183‑2, March

1996

[5] N.

N.: Petroleum and natural gas industries – Steel pipe for pipe lines –

Technical delivery conditions. ISO 3183‑3, April

1999

[6] N. N.: Specification for

Line Pipe. API Specification 5L, 43rd Edition, March 2004

[7] Wärme

entsteht direkt im Werkstück. Eldec Schwenk Induction GmbH,

www.eldec.de

[8] DIN 48600: Industrielle

Elektrowärmeeinrichtungen – Leistungsmessung an Hochfrequenzgeräten für

Induktionserwärmungseinrichtungen ‑ Messverfahren zur Bestimmung der

Ausgangsleistung von HF‑Generatoren. February, 1979

[9] Beitz, W.; Küttner, K.‑H.:

Dubbel – Taschenbuch für den Maschinenbau. 18th edition,

Springer‑Verlag, 1995

[10] Schwetje, T.: Untersuchungen

zum Hochfrequenzschweißen von Konturbauteilen. Dissertation, TU

Clausthal, 2002

[11] Dilthey, U.:

Materialsammlung zur Vorlesung Schweißtechnische Fertigungsverfahren I

“Schweiß‑ und Schneidtechnologien”. ISF RWTH Aachen (www.isf‑aachen.de)

[12] Matthes,

H. G.; Jürgens, R.: HF‑Rohrschweißen mit

IGBT‑Reihenschwingkreisumrichter. iew – Industrielle Elektrowärme, 56

(1998) 4

[13] Leistungsschalter

für Schweißinverter – Thyristor, BJT, FET und IGBT. Kemppi GmbH

(www.kemppi.com)

[14] Asperheim, J. I.; Grande, B.; Markegård, L.; Buser, J. E.; Lombard, P.:

Computation and analysis of temperature distribution in the

cross‑section of the weld Vee. Tube Int., Nov.

1998

[15] Asperheim, J. I.; Grande, B.: Temperature Evaluation of Weld Vee

Geometry and Performance. Tube Int., Oct. 2000

[16] Grande, B.; Asperheim, J. I.: Factors Influencing Heavy Wall Tube

Welding. Tube & Pipe Technology, March/April 2003

[17] Scott, P.: The Effects of

Frequency in High Frequency Welding. Transactions of Tube 2000, Toronto,

ITA Publication (www.tubenet.org.uk)

[18] Morin, T.; Scott, P.: Modern

Methods of High Frequency Welding Used to Produce Conistent Quality.

www.tubenet.org.uk

[19] Gardiner, D.: Variable Frequency on Demand – The Ultimate in Flexibility

for Today’s Tube and Pipe Producers. Tube & Pipe

Technology, July 2003

[20] Quaglia, A.: Selecting the

right H.F. Generator.

www.tubenet.org.uk

[21] www.sms‑elotherm.com

[22]

www.emmedi.it

[23] www.thermatool‑europe.com

[24] www.efdinduction‑usa.com

[25] www.efd‑induction.com

Mannesmann

Fuchs Rohr GmbH

Kissinger Weg

D-59067 Hamm

Germany

E‑mail:

hendrik.loebbe@mannesmann‑fuchs.com

Website:

www.mannesmann-fuchs.com

|

|