CONAS

Continuous Narrow Strip Production

Line

for Welded Copper Tubes

by

Mannesmann Demag Corporation

Dr. Erling Roller, Peter Kalkenings & Karl Heinz Häusler

Introduction

The worldwide production of semi-finished products of copper and copper alloys totals around 14 - 15 million tonnes per year, with annual growth rates of approx. 3%. Tubes make up roughly 10% of this figure. Important producer regions are Western Europe (36%), America (20%), Asia including Australia (27%). The remaining 17% are spread over the rest of the world.

Whereas in some Western European countries, the relevant standards require that installation and ACR tubes of copper are produced by seamless methods, the ASTM standards which are also employed in Asia also allow welded tubes. A further expansion of the use of welded tubes has been prevented to date by the high production costs for the cold rolled strip. For some time now, however, an increasing trend towards welded tubes has been observed due to the better surface quality and closer dimensional tolerances. This trend is taking place worldwide and has already taken over in the production of finned ACR tubes. Due to the high strip costs, installation tubes are almost exclusively produced in seamless processes. An acceptance by the market for welded water pipes can only be expected when significant competitive advantages in terms of product quality and lower production costs can be achieved with a new strip production process. The production of an inexpensive cold-rolled strip could thus revolutionise the copper tube market worldwide. First of all the welding of ACR tubes would become more attractive, and secondly the large volumes of industrial and installation tubes could be produced more cost-efficiently and in a higher quality.

The Copper Plants Division of Mannesmann Demag AG owns the Contirod process for continuous casting and in-line hot rolling of wire rod for wire production. This process is already well known as a result of its low production costs and high productivity. It is also possible to cast hot roll and cold roll flat material on this line for in-line production of narrow cold strip in the ideal widths for tube welding of 65 to approx. 150 mm (CONAS process). This report describes how a CONAS line is configured and goes on to illustrate the various possibilities of tube production from the CONAS strip. Comparisons are drawn with the production of seamless tubes.

CONAS Line Concept

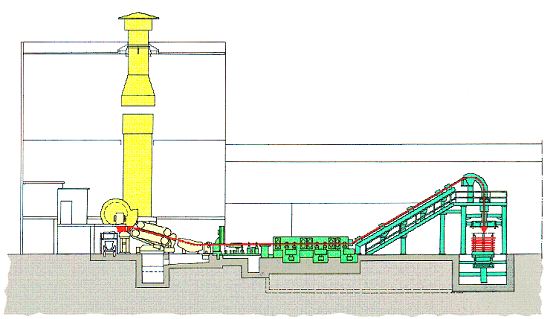

The basis for this concept is the CONTIROD System (Figure 1) for the production of copper wire rod. 32 CONTIROD lines worldwide with capacities from 5 - 60 t/h have been commissioned to date.

|

Figure 1. CONTIROD System

|

|

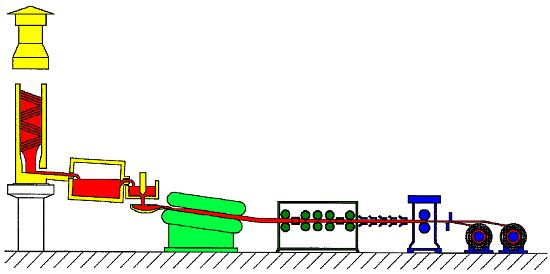

The schematic layout of a CONTIROD line comprises a melting facility, a Hazelett twin belt caster, a hot rolling mill, a cooling and pickling line and a coiler (Figure 2).

|

Figure 2. The schematic layout of a CONTIROD line

|

|

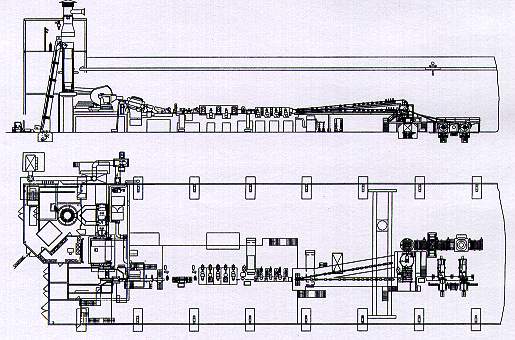

With this concept, the rectangular profile cast in the Hazelett caster can be rolled out into flat material instead of round material. A corresponding casting cross-section merely has to be selected and the sizing and number of rolling stands for the desired final size have to be calculated. The CONAS line (Figure 3) therefore has a similar fundamental configuration to that of CONTIROD lines.

|

Figure 3. The CONAS line

|

|

A melting facility, for CONAS with an induction-heated holding furnace for better control of the melt, is followed by the Hazelett caster, the hot rolling mill, the cooling and pickling line, a cold rolling stand and 2 strip coilers to take up the continuously produced strip. The cold rolling stand integrated into the CONAS line ensures that the cold strip has some mechanical strength and is far less susceptible to mechanical damage than hot strip. Furthermore, the use of the cold rolling mill offers the advantage that the strip can be rolled inline to the ingoing thickness suitable for a mother tube in a welding machine.

CONAS lines can be built with capacities from 7 - 20 t/h. Although these capacities may appear to be very high for some users, this fact is put into perspective by two other factors so that it is economically viable to install a CONAS line even for smaller tube capacities. The first reason are the generally low production costs of this line. The second reason is its versatility, since a combined CONAS/CONTIROD line (Figure 4) can be used to produce both rounds and flats in a very wide range of sizes.

|

Figure 4. Combined CONAS/CONTIROD line

|

|

As the costs for wear parts, standardised for one tonne of copper, are almost constant and the costs for consumables tend to decrease with increasing capacities, higher capacities offer major benefits with respect to cost-effectiveness (Figure 5).

|