Narrowing the gap with hot wire orbital TIG

by Ian Farmer,

Editor of Welding & Metal Fabrication Magazine

Building of power plants is a complicated task with its various pressurised vessels, turbine generators, heat exchanging plants, cooling plants and waste water plants. What links all these plant segments is the pipelines of various diameters, adding up to many miles in a plant.

In 1996 Toshiba started a project to build a conventional fossil fuel power plant in Japan. The company even created

a special division dedicated to orbital welding of pipelines, for this project plus two other projects on different

sites, although all the projects used similar tubing. Toshiba purchased two narrow gap hot wire orbital TIG

welding systems to carry out the task, the first one in 1996 and then another one in 1997.

Quicker and cheaper in the long run

Narrow gap welding is a lengthy process for which to fix the weld parameters and procedures for the welding of each type of pipe, but once set up the process is quicker. There is less space to fill with weld metal and consequently is cheaper as less consumable is used. The most important factor in narrow gap orbital welding is the preparation of the tube. Factors such as shrinkage, the different diameters, alignment, the variation in rotundity and condition of the tube all must be taken into account.

Operators aligning the guide ring prior

to fitting the Polycar 130 apparatus.

The pipeline material for the power plant was a medium carbon steel, STPG 38 type, 508mm in diameter, with a 50mm wall thickness or 356mm in diameter with a 54mm wall thickness. The joint preparation, which is dependant upon the wall thickness, was narrow gap `J' profile with a 2ø angle slope. The weld preparation was also carried out on site.

The consumable selected for the operation was a 0.9mm diameter solid wire of compatible composition used in atmosphere at wire feeding speeds reaching five metres /min.

The TIG wire was preheated prior to its introduction to the arc, a procedure that saves energy and can speed up the TIG process to close to that for cold wire MIG welding. The wire needs to be monitored closely as it enters the weld pool. In this instance the human eye was used to check the weld pool in situ, but the system does have the facility to be equipped with a close circuit camera so the weld pool can be monitored remotely. In addition to heating the wire, the tubes were preheated to 250øC using a wrap around electric "blanket" arrangement. Overall energy saving was in the region of 30%. The overall result of using the narrow gap process (using less filler material), the heating of the TIG wire and the preheating of the tube for faster welding speeds all contributed to an productivity increase in the operation by a factor of nine.

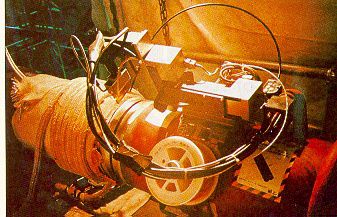

The Polycar 130 orbital welding system fitted to large

diameter pipe on site at the Toshiba built power plant.

Toshiba employed the Polycar 130 automated welding system from Polysoude which follows a prepositioned guide ring around the pipe. Up to 20 separate welding runs, including the capping run, were required. The special narrow gap torch arrangement was used only to complete approximately a third of the weld runs as the space alongside the pipeline was limited. The cramped conditions meant that a normal TIG welding torch, which took up less space, was swapped in a third of the way up the weld gap to complete the weld. In some areas the space available around the pipe was less than 360mm.

Orbital hot wire TIG narrow gap welding

in action, illustrating the special narrow

gap torch used for the parts of the weld gap.

Power was supplied from the 600 amp AutoTIG 600PCDC power source, also from Polysoude, which has an separate integral 140 amp heater solely for preheating the TIG wire. This mobile power unit is an ideal on-site machine as it can run from an engine driven generator supply, so can be loaded on to a truck and taken to where it is needed.

The welding was carried out mostly in the 5GT position and six metre sections of pipe were welded. Although no values for the time taken to complete a weld were available for this particular set-up, a similar arrangement on a 290mm diameter pipe with a 23mm wall thickness took 1 hour 13 minutes to complete the welding operation.

Although post weld finishing of the weld had been planned, the resultant quality of the welds produced and the final smoothness eliminated the need to employ any post weld grinding and finishing. This not only saved money but also time, increasing productivity even further.

Training the operators

Initially, training of the Japanese operators in the use of the equipment was given by Polysoude, which supplied a tutor, in addition to a local instructor from Polysoude's Japanese distributor.

The Polycar semi-automated orbital welding system together with the Autotig 600PCDC has since been employed, on-site, in a number of orbital welding projects with success.

Further Information:

Polysoude S.A.

Z.I. du Bois Briand, 2, rue Paul Beaupere, BP 41606,

F-44316 Nantes Cedex 3, France

Fax: +33 240 681111

Email:

WWW: www.polysoude.com

|