|

T-DRILL COLLARING AND FLANGING

T-DRILL is a manufacturer and world wide supplier of pipe fabrication machines.

Last 30 years T-DRILL has been manufacturing various kinds of Pipe fabrication

machines. This article introduces T-DRILL Collaring and Flanging machines.

Collaring

Everyone who has been making welded T-joining of steel pipes knows that it

can take a long time. With T-DRILL Collaring machines this time can be reduced

dramatically. At the same time, the joint quality will be improved.

T-DRILL Collaring machines are designed for forming of trimmed (faced) collars

on a pipe, suitable for butt-welding (See figure 1).

| |

Figure 1. Collar description

|

|

Collars also allows the use of orbital welding. In this way the difficult work to make welded pipe joints can be changed to easy job. Also the use (and cost) of TEE-Fittings can be eliminated. The T-DRILL Collaring method can be used for cold forming of all malleable materials like Stainless Steel, CuNi and Mild Steel.

Collaring process

The collaring process consist of three steps:

1. Elliptical hole cutting

| |

Figure 2. Milled pilot hole ready for collaring

|

|

Elliptical hole is produced with milling. First the End Mill is drilled through the pipe's wall. Optimum elliptical pilot hole is milled with automatic cycle including lubrication.

2. Collaring

| |

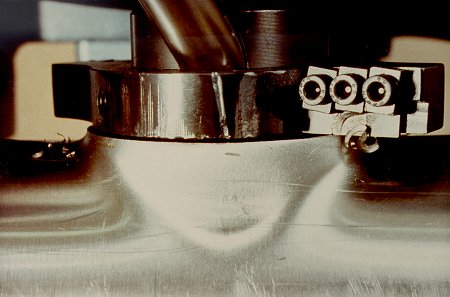

Figure 3. Collar forming process

|

|

Collaring Head (collaring tooling) is inserted into the elliptical hole. After that

follows an automatic collaring cycle where forming pins are extruding the pipe material

outwards through the pilot hole, thus, forming a collar.

3. Trimming

| |

Figure 4. Trimming of collar

|

|

After collar is formed, the surface is almost flat, but it is still quite rough. Therefore, it

needs to be trimmed smooth. This provides best circumstances for easy butt-welding.

All above three steps are carried out in a same workstation by single operator.

The process times depends on the collar diameter (21.3 - 168.3 mm) and they are between

2 - 7 minutes.

Flanging

Flanging (also called Van Stone, lap-joint or loose flanging) forms a flanged

pipe connection. Lips and flanges are formed directly on the end of the pipe - a system that saves up to 40% in both time and costs compared with traditional weld neck flange connections.

Flanging has been used extensively in the following industries:

- Chemical

- Pulp and paper

- Shipbuilding

- Power plants

- Offshore oil rigs

- Petroleum

- District heating

- District cooling (New application!)

Flanging eliminates the need for welding, since the flange is mounted loosely behind the formed pipe-end configuration. It allows carbon steel flanges to be used on stainless pipe applications and also allows simpler pipe installations, since the need for pipe/flange alignment is eliminated. Flanging also eliminates the need to X-ray the weld.

| |

Figure 5. Flange description and dimensions

|

|

Depending on the conditions of use, DIN standards 2641 and 2642 or standards derived from these can be used for dimensioning. The main factor, which definites the maximum diameter of the flange is deforming capability of material. In practice this capability is expressed as

elongation. This means that the proportion d4/OD should be smaller that the elongation value of material to be flanged. However, the experimental results show that much higher

elongation values can be achieved thanks to the multidimensional straining scheme.

In hot forming the sealing surface can be varied in quality from smooth to rough by selecting the appropriate profile for the forming cone.

| |

Figure 6. Ready flanged pipe-end

|

|

|