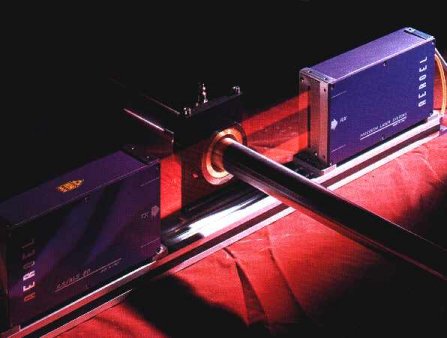

Diameter control for bars and tubes

The Barline is a laser measurement system, which has been specially designed

for use on-line, for diameter control and monitoring of metallic ground bars

and drawn tubes.

The Barline system will gauge the diameter and ovality from 0.1 to 200mm

using either single or dual axis laser gauges. The software compares the

measured values with the nominal diameter and pre-set tolerances allowing

machine regulation and pre-alarms to be generated.

The laser gauges used in the Barline system offer the user our patented

self-calibration technology allowing drift-free measurements and no size

re-mastering. In addition, using a fast 400Hz scanner, resolutions of 0.1Ám

are achievable. The measurements taken are completely unaffected by product

vibration ensuring continuous valid readings. Specially designed cleaning

devices are supplied so that oil and dirt is removed prior to measurement.

The bars are kept with-in control limits by providing automatic regulation

to the grinder control system, which in turn adjusts the grinder wheels.

This has the advantage of significantly improving product quality, as

inspection of components is 100% on-line. Thus resulting in a large

reduction in waste, no product returns from customers and considerable

savings in labour costs.

Drawn products are measured in the same way. Here machine regulation is not

possible, however, by comparing the measured values with the nominal

diameter and pre-set tolerances, we are able to generate alarms alerting the

operator that the die is worn out and requires replacement. Product quality

and reduction in scrap is afforded here as well as no product returns from

customers.

As measurements are taken continuously on the bar, full statistical analysis

is performed for each bar and every bundle. The maximum, minimum and average

values are all recorded for printing.

Traditional methods of inspection, taking a random sample from the batch to

indicate the quality of the whole batch, can result in oversights and are

time consuming. Using the Barline system eliminates the possibility of

errors, as the inspection is 100%. When large proportions of a companies

business relies on maintaining a reputation for supplying 1st class quality

products, this type of laser based inspection becomes essential.

For further information please contact:

Ben Paul

SCANTRON

Monarch Centre

Venture Way, Taunton, Somerset, TA2 8DE

Tel: 01823 333343

Fax: 01823 333684

WWW. http://WWW.scantron-net.co.uk

Email.

|