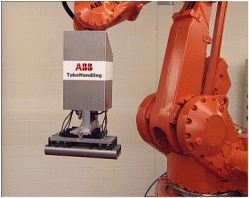

ABB TubeHandling-System

Preamble

ABB TubeHandling, a specific packaging solution for the tube industry is a new development from ABB Flexible Automation.

This solution is well proven and does the best “stacker” work for several leading companies

ABB robot IRB4400 with gripper

|

Description of TubeHandling

An ABB’s six-axis pallet robot automatically produces all standard tube pallet patterns for a variety of containers. By entering the tube and pallet pattern parameters, the positions of the tubes are automatically calculated; there is no need to teach the robot positions manually. Container tolerances can generally be compensated for when entering the parameters. Grip sensors stop the robot immediately if the tubes or containers are out of position.

The TubeHandling-System (THS) comes with one or two pallet points as standard, THS100 left/right and THS200.

Example of containers

|

The following tasks can be performed:

- Even palletising in rows and columns

- Stacks of hexagonal arrangements

- Optional handling of between 1 and 9 tubes per stroke

- Placing into various containers, such as pallets, wire mesh boxes or other

Summary Tube ranges

- Tubes: O.D. 10 to 150 mm

- Length: 100 to 2000 mm

- Weight: less than 35 kg/cycle

Performance data for TubeHandling-System

- Handles up to 4050 tubes/hour

- Conversion times of 5-10 minutes

Benefits

- Uses equipment to its full potential

- Enables continuous production

- Short payback

- Dehumanisation

- Reduction of noise

Overview of pallet patterns

|

Description of TubeWorks

TubeWorks is a user friendly, Windows-based interface. It allows parameter sets to be entered and logged in a simple way. These parameter sets are necessary for the steel tube palletising system. At the same time, most of the data is checked for plausibility when it is entered. This means that incorrect parameter sets can be recognisedand corrected before production starts.

Further information :

|